Core Research Facilities June 2024 Newsletter

June 2024 Newsletter

Welcome to the ASU Core Facilities Newsletter. We are ready to support all your research goals. Please follow our LinkedIn page for additional resources and community information.

Instrument Design and Fabrication Core Employee Highlight

The Instrument Design and Fabrication (IDF) Facility offers a wide range of services for ASU researchers, peer institutions and private industry partners. With expert staff and capabilities from our Electronics and Machine Shops, we are ready to help you accomplish your project goals.

Meet the IDF Team

Brian Ipema, Director

Brian Ipema manages the the Machine and Electronics Shops as the IDF Core's Operations Director. With an engineering background in material analysis, design and manufacturing, his expertise lies in scientific research and development prototyping. Brian has supported diverse organizations, from Medtronic and Intel to the DoD. He is certified in SolidWorks, among other professional certifications.

James Makar, Machine Shop Manager

James "Jim" Makar joined ASU in 2004, leveraging his vast experience in the semiconductor, aerospace and robotics industries to manage the IDF Core's Machine Shop. Jim finds turning initial concepts into completed projects with researchers and faculty "tremendously rewarding."

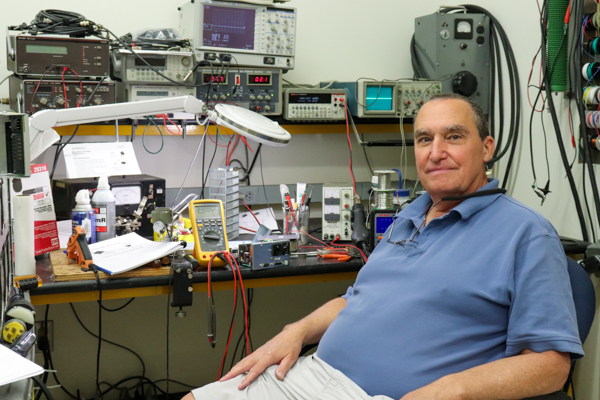

Daniel Saine, P.E., Electronics Shop Manager

Daniel "Dan" Saine, a registered Professional Electrical Engineer, manages the Electronics Shop. He has experience in RF, digital and analog systems. Notable projects include the International Space Station's power system, the Army FIST communications system and the first CAT scan X-ray processor.

Gerald Lacy, Senior Instrument Maker and Designer

Gerald "Jerry" Lacy joined ASU in 2016 as a Senior Instrument Maker Designer specializing in machining, mechanical design and assembly. His work supports research on brain injury and virus characterization. He has contributed the CXFEL and various NASA projects. Certified in SolidWorks, he brings expertise from many industries.

Chris Bello, Machinist

Christopher "Chris" Bello joined the IDF Core in July 2023, with a rich background as a machinist specializing in aerospace and semiconductor parts. Chris brings expertise honed through a 6400-hour apprenticeship where he earned the title of Journeyman Machinist from the National Tooling & Machining Association and the Arizona Department of Labor.

Mark White, Instrument Maker

Mark White joined ASU as a Machinist/Instrument Maker in 2004, leveraging 45 years of experience across semiconductor, aerospace, tool and die and agricultural and mining equipment repair. He thrives on solving complex problems and meeting the diverse functional and material demands in ASU's dynamic setting.

"It is also rewarding being able to work with and learn from our customers since so many of them are degreed faculty in a variety of fields and disciplines which contributes to my overall understanding of the world we live in. - Mark White

Brian Smith, Instrument Maker

Brian Smith has been a machinist in the manufacturing industry for 25 years, with a focus on aerospace. Brian joined ASU Instrument Design and Fabrication Core in 2016 specializing in CAD modeling and enjoys collaborating with clients on their design projects.

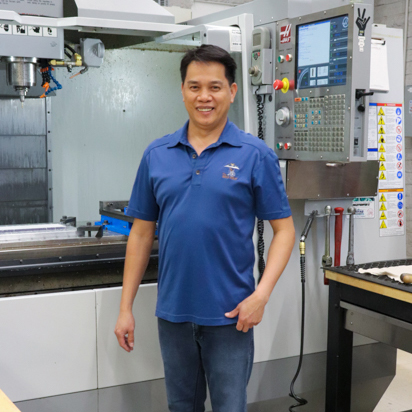

Tan Nguyen, Senior Machinist

Tan Nguyen is a Senior Machinist for the IDF Core, briniging experience from the aerospace, defense and semiconductor industries. He specializes in sketching solid model parts, programming and preparing CNC machines to create essential components for research initiatives.

More about the team and their successes.

IDF News

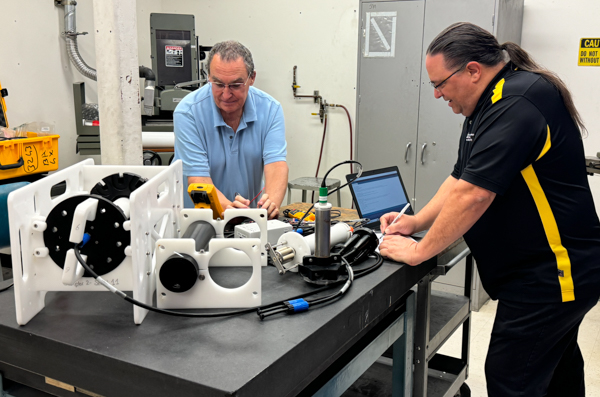

IDF and the ASU Bermuda Institute of Ocean Sciences

Brian and Dan have been working with Dr. Yvonne Sawall from ASU BIOS on an NSF-funded project studying eddies in coral reefs. The BIO-RESORT is an instrument engineered to measure the metabolic rates or marine organisms in the field. Here, we can see them as they rebuild and update the CPU for the water sampling units crucial to the BIO-RESORT's functioning.

How the water sampling units support the BIO-RESORT.

Employees of the IDF Core are proud to have received an ISO 9001: 2015 and AS9100D certification

Compliance to ISO 9001:2015 and AS9100D requirements is the basis for organizing and operating our quality management system.

The IDF Core "has demonstrated its commitment to world class quality by implementing and becoming certified to the ISO 9001: 2015 and AS9100D standard. They have joined an elite number of organizations worldwide who have achieved certification to this globally recognized quality standard,” said Randy Daugharthy, Vice President – Registrar at the Performance Review Institute Registrar.

New Maching Shop Equipment

The Hexagon Scan+

A versatile 900 x 1200 x 800mm Coordinate Measuring Machine, designed for detailed assessments of size and form with superior tactile scanning capabilities.

Tactile scanning enables the Scan+ to collect numerous surface points rapidly, ensuring precise form and profile evaluations for various parts. This machine integrates tactile scanning with an adaptable automatic probe head, facilitating the examination of intricate components from multiple angles.

The integrated styli changer rack enhances efficiency, allowing swift transitions between styli configurations during measurements, all without compromising the measurement scope.

More Instrument Design and Fabrication Equipment.